The crankshaft is essential to your engine. It converts the pistons’ up-and-down movement into the spinning force powering your car. If damaged or broken, your engine won’t run properly—or at all.

For mechanics, a broken crankshaft signals severe engine damage, sudden breakdowns, and high repair costs. Unlike a worn belt or faulty sensor, the crankshaft rarely fails quietly. By the time symptoms appear, the engine may already be in complete failure.

Spotting early warning signs helps prevent damage from spreading to other engine parts, such as connecting rods, bearings, or the block. That’s why every car owner should know broken crankshaft symptoms.

What Is a Crankshaft and What Does It Do?

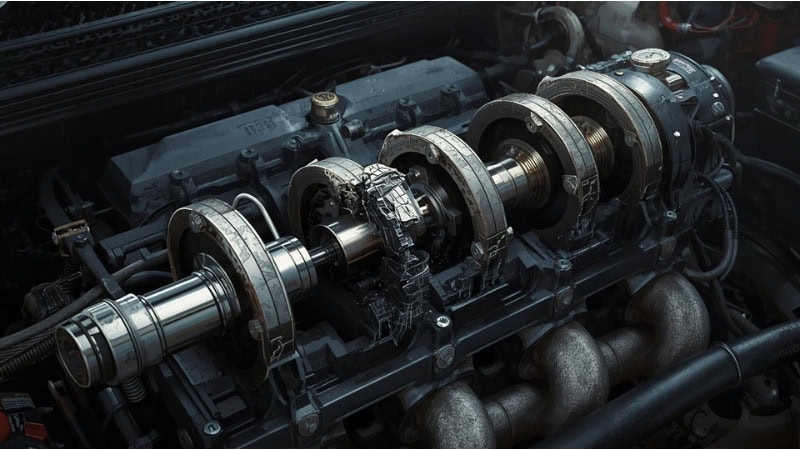

The crankshaft, a heavy, precision-machined steel part at the engine’s base, converts pistons’ linear motion into rotation to drive the transmission and wheels. Each piston’s movement is transferred through connecting rods to the crankshaft.

In a properly functioning engine, the crankshaft spins thousands of times per minute while supporting the extreme forces generated by combustion. It also rides on a thin film of engine oil, which prevents metal-to-metal contact between the crankshaft journals and the bearings. If that lubrication fails, damage can begin very quickly.

Because the crankshaft is tied directly to the pistons, bearings, and timing components, any crack, bend, or break affects the entire engine. This is why crankshaft damage often leads to a complete engine shutdown rather than a simple drivability issue.

Common Broken Crankshaft Symptoms

A broken or damaged crankshaft often shows several warnings before total engine failure. Spotting these early can save you from expensive repairs or full engine replacement.

- Unusual knocking or deep clunking noises: A bent or cracked crankshaft can cause loud knocks, especially when the engine is idling or running at low speed.

- Sudden loss of engine power or rough running: If the crankshaft isn’t spinning smoothly, your engine might lose power, run rough, or even misfire.

- Engine stalling or won’t start: Serious crankshaft problems can make it hard or impossible to start your engine.

- Excessive engine vibration: You may feel strong vibrations at idle or while accelerating due to an imbalance in the crankshaft rotation.

- Oil pressure warning light or sudden drop in oil pressure: Crankshaft damage can hurt the main bearings, causing oil pressure to fall.

- Metal shavings in engine oil: Cracks or wear on the crankshaft can leave tiny metal pieces in your oil, which might show up during an oil change.

- Check engine light: Modern cars may turn on the check engine light and store fault codes for misfires, low oil pressure, or other engine issues.

Most of these symptoms start off small but get worse quickly if you ignore them. A mechanic will usually need to check things out to confirm the problem.

What Causes a Crankshaft to Break

A crankshaft can fail due to several mechanical or maintenance-related issues. One of the most common causes is oil starvation. Without proper lubrication, the bearings and crankshaft journals experience metal-to-metal contact, which quickly leads to cracks or warping. Bearing failure, often due to wear or oil contamination, can also place extreme stress on the crankshaft.

Over-revving the engine or consistently operating it under heavy load can exceed the crankshaft’s designed strength, leading to bending or cracking. Manufacturing defects or metal fatigue over time may weaken the crankshaft, making it prone to failure even under normal driving conditions. Sudden mechanical shocks, such as hydrolock from water entering the cylinders, can also instantly break a crankshaft.

Regular maintenance, careful driving, and timely repairs reduce the risk of crankshaft failure.

How Mechanics Diagnose a Broken Crankshaft

Diagnosing a broken crankshaft requires careful inspection and testing. Mechanics often start by listening for unusual noises, such as knocking or clunking, while the engine is running, which can indicate bending or cracks. Oil inspection is another key step; metal shavings or unusual debris in the oil often point directly to crankshaft damage.

Compression and leak-down tests help identify whether cylinders are losing pressure, which can be a sign of crankshaft misalignment or bearing failure. In more severe cases, mechanics may partially dismantle the engine to visually inspect the crankshaft and connecting rods. Advanced tools such as borescopes (tiny cameras) or scan tools (electronic diagnostic devices) can also be used to find engine misfires or vibration patterns that match crankshaft issues.

Early, accurate diagnosis is crucial. Delaying can lead to catastrophic failure and far higher repair costs.

Can You Drive With a Broken or Cracked Crankshaft?

Driving with a broken or cracked crankshaft is risky and strongly discouraged. Even a small crack can quickly cause complete engine failure. Driving can destroy connecting rods, pistons, bearings, and the engine block.

In some cases, the engine may still start or run for a short distance, but the vibrations, power loss, and abnormal noises will worsen quickly. Two services are usually the safest option once crankshaft damage is suspected. Continuing to drive can turn a repairable issue into a total engine replacement scenario, dramatically increasing costs and downtime.

Preventive action and early diagnosis help avoid dangerous, expensive engine outcomes.

Repair Options: Fix or Replace?

When a crankshaft is damaged, mechanics decide whether to repair or replace it. Small cracks or minor bends may be repaired by grinding or machining, with bearing replacement as needed. These repairs only work if the damage is minor and hasn’t harmed other engine parts.

In most cases, severe crankshaft failure requires either a complete crankshaft replacement or a full engine rebuild. Rebuilding involves replacing damaged bearings, rods, and, sometimes, pistons, as well as the crankshaft. While repair may save money initially, engine replacement is often more reliable and ensures long-term performance.

Deciding between repair and replacement depends on the extent of damage, labor costs, and vehicle value, and should always be guided by a professional mechanic’s assessment.

Cost to Repair a Broken Crankshaft

Repairing or replacing a broken crankshaft is one of the more expensive engine repairs. Labor alone can range from 10 to 20 hours, depending on the engine layout, and the cost of parts—especially a new crankshaft and bearings—can be substantial. On average, U.S. repair costs range from $1,500 to $4,000, but complex engines or high-end vehicles can exceed $5,000.

Factors affecting the total cost include the extent of engine damage, the availability of replacement parts, and whether a full engine rebuild is necessary. Sometimes, replacing the entire engine is more cost-effective than repairing a severely damaged crankshaft, particularly for older vehicles. Early detection can significantly reduce repair costs by limiting secondary engine damage.

How to Prevent Crankshaft Failure

Prevent crankshaft failure with proper maintenance and driving. Regular, correct oil changes are critical, as poor lubrication is a leading cause of damage. Monitor oil levels and check for contamination during routine service to catch early wear.

Avoid over-revving the engine or consistently carrying heavy loads, as this puts excessive stress on the crankshaft and connecting rods. Address engine misfires, unusual noises, or vibrations immediately, because ignoring them can accelerate crankshaft damage. Choosing high-quality replacement parts during any engine repair also helps maintain the crankshaft’s long-term integrity.

Preventive care is always cheaper and safer than repairing or replacing a broken crankshaft.

FAQs

1. Can a crankshaft crack without making noise?

Yes, small cracks in the crankshaft can develop silently at first. Drivers may not notice problems until the crack spreads. Silent cracks may go undetected until balance, oil pressure, or misfires become issues. Routine maintenance and oil checks can reveal metal particles or early stress. Mechanics might catch subtle vibrations in running tests. Waiting for noise can cause catastrophic failure—early diagnosis is safest.

2. What does a broken crankshaft sound like?

A broken or severely damaged crankshaft typically produces loud knocking or clunking noises. The sound is often deep and rhythmic, corresponding with the rotation of the crankshaft and piston movement. You may also hear grinding or tapping if bearings are failing alongside the crankshaft. These noises usually worsen with engine speed or load. Minor crankshaft damage may produce subtle knocking that is easy to miss, so even faint irregular sounds should be checked by a professional. Ignoring these noises can lead to sudden engine failure.

3. Will a broken crankshaft trigger the check engine light?

Yes, a broken or misaligned crankshaft can trigger the check engine light. Modern vehicles monitor engine performance, misfires, and oil pressure. Crankshaft issues can cause irregular rotation, resulting in misfire codes, low oil pressure warnings, or crankshaft position sensor errors. However, the check engine light may not appear immediately, especially with small cracks. It’s important not to rely solely on warning lights; unusual noises, vibrations, or power loss are also indicators. Mechanics often use diagnostic scan tools to read stored codes and correlate them with physical crankshaft inspection.

4. Is crankshaft failure sudden or gradual?

Crankshaft failure can be both gradual and sudden, depending on the cause. Gradual failure often occurs due to metal fatigue, worn bearings, or poor lubrication. Drivers may notice subtle knocking, vibration, or minor power loss before a complete failure. Sudden failure typically results from extreme stress, hydrolock, or severe mechanical shocks. In these cases, the engine can seize instantly, resulting in a total loss of power and potential collateral damage. Recognizing early warning signs and performing timely maintenance is essential to prevent a sudden, catastrophic event.

5. Can low oil alone break a crankshaft?

Low oil levels themselves may not directly break a crankshaft, but they can lead to conditions that cause failure. Insufficient lubrication increases friction between the crankshaft journals and bearings, generating heat and wear that can lead to cracks or bending over time. Low oil levels also reduce oil pressure in the oiling system, potentially starving critical engine parts of lubrication. If ignored, this can lead to bearing failure, uneven stress on the crankshaft, and eventual breakage. Regularly checking oil levels, using the correct oil type, and performing timely oil changes are crucial to prevent crankshaft damage indirectly caused by low oil levels.

6. How long does a crankshaft last under normal conditions?

Under normal driving and maintenance conditions, a crankshaft can last the lifetime of the engine, often over 200,000 miles for most vehicles. Longevity depends on proper lubrication, high-quality manufacturing, and avoiding extreme stress, such as over-revving or carrying heavy loads. Regular oil changes, timely replacement of worn bearings, and attention to engine health all extend crankshaft life. However, engines with poor maintenance or frequent mechanical stress may experience crankshaft problems much earlier. Monitoring for early symptoms and performing preventive maintenance is key to ensuring the crankshaft functions reliably for decades.

7. Can a broken crankshaft be repaired, or does it always require replacement?

Minor crankshaft damage, such as small cracks or slight bending, can sometimes be repaired through machining, grinding, or welding, followed by new bearings. However, most severe crankshaft failures require complete replacement or a full engine rebuild. Repair feasibility depends on the extent of damage and whether the crankshaft has caused secondary engine issues. Rebuilding the engine often involves replacing rods, bearings, and pistons along with the crankshaft. Mechanics assess repair versus replacement based on reliability, cost, and vehicle value. In many cases, replacement ensures long-term engine performance and prevents future failures.

Conclusion

Knowing how to tell tire size is more than just reading numbers on the sidewall—it’s about safety, performance, and protecting your vehicle. Each component of a tire size, from width and aspect ratio to load index and speed rating, plays a specific role in how your car handles, brakes, and rides. Mechanics always verify tire specifications before replacing or upgrading tires to prevent uneven wear, suspension issues, and potential safety hazards.

For everyday drivers, the easiest way to get the right size is to check the sidewall, door jamb sticker, or owner’s manual. For modified, performance, or heavy-duty vehicles, professional guidance ensures that any changes won’t compromise safety or drivability. Taking the time to read and understand tire size keeps your car running smoothly and your passengers safe.