Calipers are essential measuring tools in American automotive shops, machine rooms, and fabrication garages. They deliver quick, reliable measurements for tasks like checking brake rotor thickness or verifying shaft diameters, supporting efficient workflows. Unlike rulers or tape measures, calipers offer the precision needed for tight tolerances in mechanical and machining work. This article reviews the main types of calipers and their uses, providing practical guidance for professionals and dedicated DIY users. Visual aids may be added later to further illustrate each caliper type.

What Is a Caliper?

A caliper is a precision instrument used to measure external and internal dimensions, as well as depths, with high accuracy. In most American shops, calipers are used to measure to the thousandth of an inch. The jaws slide along a calibrated scale to determine exact component sizes. While micrometers offer greater precision, calipers provide better speed and versatility. Compared to rulers, calipers deliver much higher accuracy. This balance of speed and precision makes calipers indispensable in automotive repair, machining, metal fabrication, and general mechanical work.

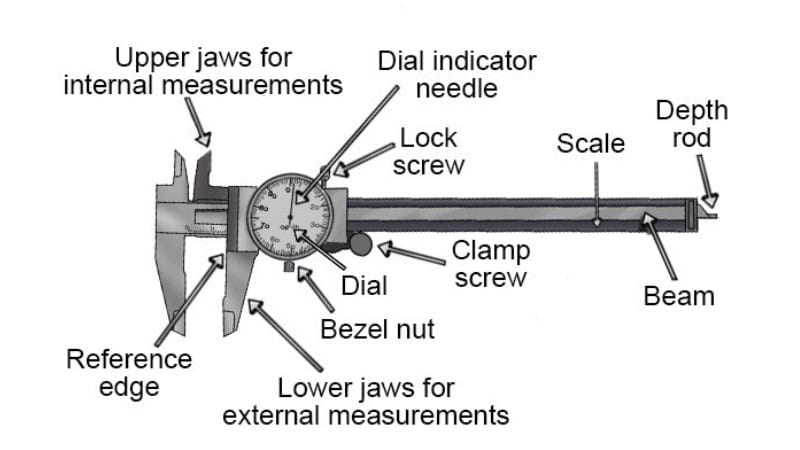

Main Parts of a Caliper

Most calipers consist of the following basic parts:

- Outside jaws – Used to measure external dimensions.

- Inside jaws – Used to measure internal diameters.

- Depth rod – Used to measure the depth of holes or slots.

- Main scale – Displays measurements in inches or millimeters.

- Vernier, dial, or digital display – Indicates measurement readings.

- Lock screw – Secures the measurement while it is being recorded.

Different Types of Calipers and Their Uses

1. Vernier Caliper

The vernier caliper is a manual measuring instrument commonly used in machine shops and training programs. It operates without batteries or electronics, relying on engraved scales. Vernier calipers are valued for their durability and reliability, especially where digital tools may fail. They are often used to measure shafts, bushings, and other machined components that require high accuracy. However, reading a vernier scale requires practice and attention, which can slow efficiency in fast-paced settings. As a result, machinists and inspectors use vernier calipers more frequently than automotive technicians, who typically need faster measurements.

2. Dial Caliper

Dial calipers are widely used in American automotive and production shops for their accuracy and readability. The dial face clearly shows even minor measurement changes, making it easier to detect variations when inspecting parts such as brake rotors and bearings. Since they do not require batteries, dial calipers are dependable for long-term use. However, their internal gears can be affected by dirt, metal shavings, or impact, so regular cleaning and careful handling are necessary to maintain accuracy. Many mechanics prefer dial calipers for inch-based measurements, especially when inspecting multiple parts and needing both speed and consistency.

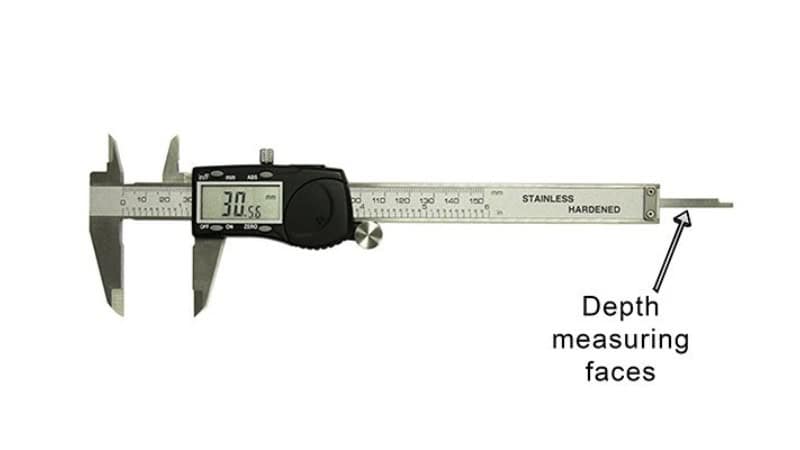

3. Digital Caliper

Digital calipers are now the primary measuring tool in most modern shops. They provide instant readings, can be zeroed at any point, and easily switch between inches and millimeters. These features make them convenient for routine automotive and fabrication tasks. Mechanics often use digital calipers to measure bolts, tubing, spacers, and hardware. While digital calipers are accurate and efficient, their reliability depends on build quality. Lower-cost models may have measurement drift or battery issues. Professionals usually choose mid-range or premium digital calipers for consistent accuracy and durability.

4. Inside Caliper

Inside calipers are specialized tools for measuring internal dimensions that standard caliper jaws cannot reach. Unlike digital or dial calipers, they do not provide direct readings; instead, they transfer the measurement to another device, such as a ruler or micrometer. Inside calipers are commonly used for cylinder bores, pipe interiors, and large internal cavities. They are especially useful in traditional machining or large-scale fabrication where electronic tools may not be suitable. Although they lack precision readouts, inside calipers are valuable for rough measurements and layout work.

5. Outside Caliper

Outside calipers are mainly used to measure external dimensions but are not intended for high-precision work. They are common in fabrication shops, welding environments, and traditional metalworking. Outside calipers are often used to compare sizes, check round stock, or transfer measurements rather than provide exact values. Their simple construction increases durability and resistance to the rigors of workshop conditions. Since they do not provide direct readings, accuracy depends on the operator’s skill and the secondary measuring device. Outside calipers are best for rough measurements where high precision is not required.

6. Depth Caliper

Depth calipers are designed to measure the depth of holes, slots, and recessed surfaces. Many digital and dial calipers include a depth rod, allowing them to serve this function without extra equipment. Accurate depth measurements are essential in automotive and machining work, such as verifying drilled holes or machined pockets. Proper technique is important, as the caliper base must rest flat on the reference surface for correct readings. Depth calipers are often used in engine work, transmission repair, and CNC preparation. When used correctly, they provide fast, accurate depth measurements across various shop applications.

Common Mistakes When Using Calipers

- Measuring dirty or oily parts

- Forgetting to zero digital calipers

- Measuring hot components

- Applying excessive jaw pressure

FAQ

FAQ 1: Which type of caliper is best for automotive mechanics?

For most automotive mechanics, a digital caliper is the most versatile choice. It is fast, easy to read, and well-suited for tasks like measuring brake rotors, bolts, spacers, and tubing. The ability to zero at any point and switch between inches and millimeters improves repair efficiency. While dial calipers are still popular, digital calipers are generally more efficient in modern US garages.

FAQ 2: Are digital calipers accurate enough for professional use?

Quality digital calipers offer sufficient accuracy for most professional automotive and fabrication work. Most reputable models are accurate to within ±0.001 inch, which is adequate for brake, suspension, and general mechanical measurements. However, accuracy depends on proper use and maintenance. Keeping the jaws clean, zeroing before measurement, and choosing reliable brands are essential for consistent results in professional settings.

FAQ 3: What is the difference between a caliper and a micrometer?

The main difference between calipers and micrometers is their precision and intended use. Calipers are versatile and can quickly measure external, internal, and depth dimensions. Micrometers provide greater precision but are usually limited to specific ranges, often external dimensions. In US shops, calipers are used for most routine measurements, while micrometers are reserved for tasks requiring critical tolerances, such as engine internals or high-precision machining.

FAQ 4: Why do some machinists still use vernier calipers?

Many machinists prefer vernier calipers for their durability and independence from batteries or electronics. Vernier calipers also encourage careful measurement techniques and a strong understanding of precision scales. In environments where electronic tools may fail due to heat, coolant, or metal debris, vernier calipers remain reliable. They are often used in training programs to teach basic measurement skills before introducing digital instruments.

FAQ 5: How often should calipers be calibrated?

In professional settings, calipers should be checked regularly for accuracy, especially with daily use. Full calibration may be needed once or twice a year, but zero checks are recommended before each use. If a caliper is dropped, contaminated, or gives inconsistent readings, inspect it immediately. Consistent accuracy is essential when working with tight tolerances in automotive or machining work.

FAQ 6: Can calipers measure depth accurately?

Calipers can measure depth accurately when used correctly. Most digital and dial calipers have a depth rod for this purpose. For accurate readings, the caliper base must rest flat on the reference surface, as any tilt or debris can cause errors. For most automotive and machining tasks, caliper depth measurements are sufficiently accurate.

FAQ 7: What size caliper is most commonly used?

The 6-inch caliper is the most common size in US shops. It offers enough range for most automotive and general mechanical measurements while remaining compact and easy to handle. Larger calipers, such as 8-inch or 12-inch models, are used for bigger components but are less convenient for daily use. For most mechanics and DIY users, a 6-inch digital caliper is the best starting point.

FAQ 8: How can I extend the life of my caliper?

Proper care extends the life of a caliper. Wipe the jaws clean after use, store the tool in its case, and avoid dropping it. For digital calipers, replace batteries before they fail to prevent erratic readings. Do not force the jaws or overtighten measurements. With basic care, a quality caliper can last many years in a shop environment.

Conclusion

Understanding the different types of calipers and their uses helps mechanics and machinists select the right tool for each job. Each caliper type serves a specific purpose, from high-precision machining to quick automotive inspections. While digital calipers are common in modern shops, traditional tools like vernier and inside calipers remain valuable. Using the correct caliper improves accuracy, efficiency, and work quality. In both professional garages and home workshops, choosing the right caliper ensures reliable, repeatable measurements. With proper care and technique, calipers remain essential tools in any mechanical workspace.