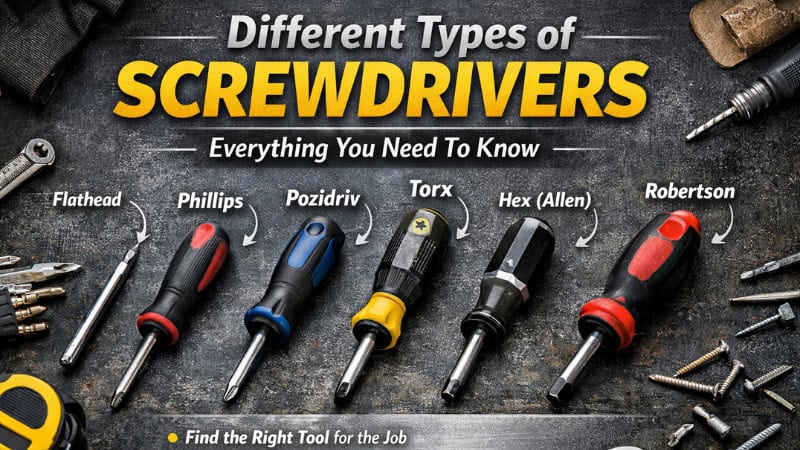

In any workspace—be it a professional auto garage or a home DIY bench—the screwdriver is an essential, go-to tool. However, using the wrong type can quickly strip a screw head, waste your time, and turn a simple job into a frustrating ordeal. Mechanics and DIYers often face tight spaces, stubborn fasteners, and torque-sensitive parts, making tool selection important. This guide covers the most common screwdriver types, their functions, and when to use each. By choosing wisely, you’ll save effort, prevent hardware damage, and maintain a professional finish.

What Is a Screwdriver?

A screwdriver is a hand or powered tool designed to drive or remove screws without damaging the fastener or surrounding material. Though it seems simple, its design details matter. Every screwdriver has three parts: the handle for grip, the shaft to transfer force, and the tip, which fits into the screw head. When choosing between manual and powered screwdrivers, consider that manual types offer more control and feedback, while powered versions increase speed and reduce fatigue. In mechanical work, using a well-made tool ensures efficient torque transfer, minimizing slippage and preventing stripped screws.

Flathead (Slotted) Screwdrivers

Flathead screwdrivers are the oldest and most basic design. They’re easy to spot by their straight, flat blade that fits into a single slot on the screw head. While often seen as outdated, flatheads are still widely used for trim work, older machinery, and simple household repairs. For mechanics, flathead drivers are versatile—but they come with some risks. If not seated perfectly, they can slip easily, damaging both the screw and nearby surfaces. That’s why professionals use them with care and only when truly needed. Despite these drawbacks, flathead screwdrivers deserve a place in every toolbox, especially since they can double as makeshift prying or aligning tools when the situation calls for it. As technology and fastening methods advanced, new driver designs emerged to address specific shortcomings—enter the Phillips screwdriver.

Phillips Screwdrivers

Phillips screwdrivers are among the most common tools in automotive, electrical, and household projects across the US. Their cross-shaped tip centers itself better in the screw head than a flathead does. Phillips screws were originally designed to “cam out” under too much torque, preventing overtightening on assembly lines. In practice, they’re easy to drive—but can still strip if used with the wrong size or too much force. Mechanics often reach for Phillips drivers when working on interior panels, dashboards, and appliance covers. Using the correct size—#1, #2, or #3—is critical, since even a slight mismatch can damage the screw. When matched properly, Phillips drivers are reliable and efficient for most medium-duty jobs. However, some specialized screws look similar to Phillips but have distinct features, such as the Pozidriv.

Pozidriv vs Phillips

Pozidriv screws look similar to Phillips screws but are not interchangeable—a common beginner’s mistake. With extra ribs between the main cross slots, Pozidriv screws handle more torque and reduce cam-out. These screws are found in European equipment, furniture, and machines. Using the wrong driver leads to poor grip and damaged fasteners, causing extra effort and frustration. If you work with imported goods or flat-pack furniture, keep Pozidriv drivers on hand. The right tool ensures control, neater work, and fewer stripped screws.

Torx (Star) Screwdrivers

Torx screwdrivers are a staple in modern automotive and industrial work. This popularity stems from their star-shaped tips, which deliver high torque with minimal slippage—ideal for both precision and strength. As a result, car makers use Torx fasteners throughout engines, brake systems, electronics, and interiors. Common sizes such as T20, T25, and T30 are frequently used in US vehicles. For mechanics, Torx screws rarely strip even under tough conditions; however, they require an exact size for a proper fit. If you’re working on newer vehicles, Torx drivers are essential.

Hex (Allen) Screwdrivers

Hex screwdrivers, or Allen drivers, have a six-sided tip for hexagonal screw heads. Common in machinery, bicycles, furniture, and some car components, hex drivers come in both metric and SAE sizes; mixing them can cause damage. Mechanics often use screwdriver-style hex drivers over L-shaped keys for better control and torque. They’re handy in tight spaces where precision matters. Ensure a proper fit, as rounded screws are hard to remove—quality tools and correct sizes are key.

Robertson (Square) Screwdrivers

Robertson, or square-drive, screwdrivers are known for their excellent grip and low risk of cam-out. While they’re more popular in Canada, they’ve gained traction in US construction and woodworking. The square-shaped recess holds the driver firmly in place, allowing one-handed operation—something mechanics appreciate when working overhead or in awkward positions. Robertson screws handle high torque without slipping, which makes them reliable for structural fastening. Though they’re not as common in automotive applications, you’ll see them in shop fixtures, crates, and equipment assemblies. If your work crosses into fabrication or construction, having Robertson drivers on hand is a smart move. For jobs that require even more specialized approaches, a variety of unique screwdriver designs are available to meet those needs.

Specialty Screwdrivers You Should Know

Not all jobs can be handled with standard screwdrivers. Specialty screwdrivers are designed for tasks that demand precision, safety, or better access. For example, precision screwdrivers are useful for electronics and small fasteners. Insulated screwdrivers are required for live electrical systems. Offset screwdrivers and stubby models help in tight or obstructed spaces. For mechanics, specialty drivers aren’t used daily, but when needed, nothing else suffices. Keeping a few on hand can save time and prevent mistakes. Understanding the array of common and specialty screwdriver types is crucial when choosing the right tool for a specific task.

Common Screwdriver Types and Their Uses

| Screwdriver Type |

Head Shape |

Common Uses |

Torque Handling |

Mechanic Tip |

| Flathead |

Straight slot |

Trim, older fasteners |

Low |

Easy to slip—use carefully |

| Phillips |

Cross |

Automotive interiors, appliances |

Medium |

Always match the size |

| Pozidriv |

Enhanced cross |

European hardware |

Med–High |

Needs correct driver |

| Torx |

Star-shaped |

Modern vehicles |

High |

Excellent torque control |

| Hex (Allen) |

Hexagonal |

Bikes, machinery |

Med–High |

Match metric or SAE |

| Robertson |

Square |

Construction, fixtures |

High |

Strong grip, low cam-out |

How to Choose the Right Screwdriver

- Always identify the screw type first, then match the screwdriver to its shape and size for the best fit.

- Check the screwdriver size against the screw slot. Using the exact fit reduces the risk of stripping.

- Choose ergonomic handles for long work sessions.

- Go insulated for electrical jobs.

- Keep both metric and SAE hex sets.

- Avoid worn or rounded tips.

- Use manual drivers for control, powered drivers for speed.

Manual vs Electric Screwdrivers

Manual and electric screwdrivers both have their place in the shop. Manual drivers give better feedback and control, which is crucial for delicate components or final tightening. They’re less likely to over-torque fasteners and are ideal for precision work. Electric screwdrivers, on the other hand, save time and reduce fatigue, especially during repetitive tasks. They’re great for interior panels, assemblies, and production work. The mistake many people make is using powered drivers for everything. From a mechanic’s standpoint, the smart move is knowing when to slow down. Speed is great—but control keeps parts intact and jobs done right the first time.

Maintenance Tips for Screwdrivers

Screwdrivers don’t require much maintenance, but neglecting them can cost you time and money. Always keep the tips clean and free of grease or debris to ensure proper grip. Inspect tips regularly—if they’re rounded or chipped, replace them. Worn tips lead to stripped screws, plain and simple. Store screwdrivers in a dry place to prevent rust, especially on the shaft. Quality tools last longer, but only if you treat them right. From a professional mechanic’s perspective, a damaged screwdriver isn’t just inconvenient—it’s a liability. Maintaining your tools keeps your work efficient, safe, and professional.

FAQ

FAQ 1: What is the most commonly used screwdriver in the US?

The most commonly used screwdriver in the US is the Phillips screwdriver, especially the #2 size. You’ll find it everywhere—from automotive interiors and appliances to home repair jobs. Mechanics rely on it for medium-duty fasteners because it centers well and is easy to drive. That said, many stripped screws come from using the wrong Phillips size, so matching the driver correctly is critical for clean, professional work.

FAQ 2: Why do screws get stripped so easily?

Screws usually get stripped because the wrong screwdriver type or size is used. Poor-quality tools, worn tips, or excessive torque also play a big role. From a mechanic’s standpoint, rushing the job is another major factor. When the driver doesn’t fully seat in the screw head, it slips and rounds off the edges. Once that happens, removal becomes time-consuming and frustrating.

FAQ 3: Are Torx screwdrivers better than Phillips?

In many applications, yes—Torx screwdrivers are better than Phillips. The star-shaped design allows higher torque transfer with much less cam-out. That’s why modern vehicles use Torx fasteners extensively. Phillips screws were designed to slip under high torque, which can be a drawback in mechanical work. If strength, precision, and repeatability matter, Torx is usually the better choice in professional settings.

FAQ 4: Can I use a Phillips screwdriver on a Pozidriv screw?

You shouldn’t. While Phillips and Pozidriv screws look similar, they are designed differently. A Phillips driver won’t fully engage a Pozidriv screw, leading to poor grip and fastener damage. Mechanics see this mistake often with European equipment and furniture. If you work on imported hardware, having proper Pozidriv screwdrivers saves time, prevents stripping, and keeps the job clean and professional.

FAQ 5: What’s the difference between manual and electric screwdrivers?

Manual screwdrivers offer better control and feel, making them ideal for precision work and final tightening. Electric screwdrivers save time and reduce fatigue during repetitive tasks. The mistake many people make is using electric drivers for everything. From a mechanic’s perspective, manual drivers are still essential. Knowing when to slow down and use hand tools prevents overtightening and damaged components.

FAQ 6: Do I really need both metric and SAE hex screwdrivers?

Yes, you do—especially if you work on mixed equipment. Metric hex screws are common in imported machinery and bikes, while SAE sizes still appear in US-made tools and older equipment. Using the wrong system might feel close, but it will round the fastener. Professionals always keep both sets because guessing costs time and can turn a simple job into a repair problem.

FAQ 7: How do I know when to replace a screwdriver?

Replace a screwdriver when the tip becomes rounded, chipped, or polished smooth. Even slight wear reduces grip and increases the risk of stripping screws. Mechanics don’t wait until a tool completely fails—damaged tips slow work and cause frustration. If the driver no longer fits snugly or slips under normal pressure, it’s time for a replacement. Good tools protect both your fasteners and your workflow.

FAQ 8: Are expensive screwdrivers really worth it?

In most cases, yes. High-quality screwdrivers are made from better steel, have precision-ground tips, and offer improved ergonomics. That means better torque transfer, less slippage, and reduced hand fatigue. Cheap screwdrivers wear out fast and damage screws, costing more time and money in the long run. From a mechanic’s point of view, quality tools pay for themselves through efficiency and reliability.

Conclusion

A well-rounded toolbox isn’t about having every tool—it’s about having the right ones. Screwdrivers may seem basic, but choosing the correct type, size, and style makes a real difference in performance and results. From flathead to Torx, each screwdriver serves a specific purpose, and knowing when to use which one separates amateurs from pros. Invest in quality tools, keep them maintained, and don’t cut corners with mismatched drivers. Whether you’re a mechanic, technician, or serious DIYer, mastering screwdriver selection helps you work faster, cleaner, and smarter. In the shop, the right tool always wins.